Description

| Sr. No. | Cable Roller Type | Roller Size (mm) | Frame Material | Roller Material | Cable Diameter Range (mm) | Breaking Load (B.L.) | Weight (Approx.) |

|---|---|---|---|---|---|---|---|

| 1 | Straight Roller | 80 × 160 | MS Welded, Powder Coated | MS / Aluminium | 10 – 100 | 1.5 Ton | 6 kg |

| 2 | Straight Roller | 100 × 200 | MS Welded, Powder Coated | MS / Aluminium | 20 – 120 | 2.0 Ton | 8 kg |

| 3 | Straight Roller | 120 × 250 | MS Welded, Powder Coated | MS / Aluminium | 30 – 150 | 3.0 Ton | 10 kg |

| 4 | Corner Roller | 80 × 160 | MS Welded, Powder Coated | MS / Aluminium | 10 – 100 | 1.5 Ton | 7 kg |

| 5 | Corner Roller | 100 × 200 | MS Welded, Powder Coated | MS / Aluminium | 20 – 120 | 2.0 Ton | 9 kg |

| 6 | Manhole Roller | 120 × 250 | MS Welded, Powder Coated | MS / Aluminium | 30 – 150 | 3.0 Ton | 12 kg |

| 7 | Triple Roller | 100 × 200 each | MS Welded, Powder Coated | MS / Aluminium | 20 – 120 | 2.5 Ton | 14 kg |

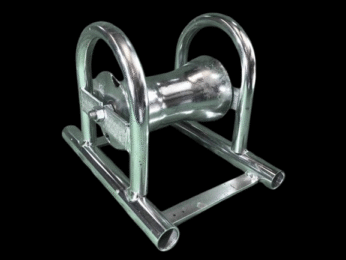

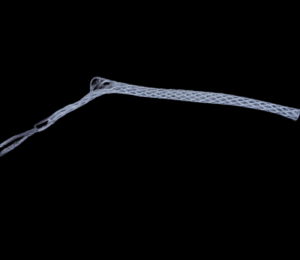

Smooth and Secure Cable Handling

Roller Cable systems are designed to guide and protect cables during installation, reducing friction and preventing damage. With heavy-duty rollers and durable frames, they ensure safe and efficient handling of cables in challenging environments such as underground works or industrial projects.

Versatile Applications Across Installations

Available in straight, corner, and triple-roller designs, these systems provide flexibility for different layouts. They are ideal for telecom networks, power distribution, and utility projects where smooth cable pulling is critical to avoid wear and tear.

Quality You Can Trust

Constructed from high-strength steel frames and nylon/aluminum rollers, Roller Cable systems deliver outstanding durability and resistance to mechanical stress. Their ergonomic design ensures smooth cable movement, reducing strain during installation. Built to last, they are an essential tool for professionals working with heavy cables.

Reviews

There are no reviews yet.